Metal oxide nanoparticles demonstrate uniqueness in various technical applications due to their suitable physiochemical properties. In particular, yttrium oxide nanoparticle(Y2O3NPs) is familiar for technical applications because of its higher dielectric constant and thermal stability. It is widely used as a host material for a variety of rare-earth dopants, biological imaging, and photodynamic therapies. In this investigation, yttrium oxide nanoparticles (Y2O3NPs) was used as an ecofriendly corrosion inhibitor through the use of scanning electron microscopy (SEM), Fourier transforms infrared spectroscopy (FT-IR), UV-Visible spectroscopy, X-ray diffraction (XRD), and energy dispersive X-ray spe

... Show More (4)

(4)

(2)

(2)

In this work, new Schiff bases of quinazolinone derivatives (Q1-Q5) were synthesized from methyl anthranilate. The synthesis involved three steps. In the first step, methyl anthranilate was reacted with isothiocyanatobenzene, producing the thiourea derivative K1. The second step entailed reacting K1 with hydrazine hydrate, synthesizing 3-amino-2-(phenylamino) quinazolin-4(3H)-one (K2). The third step involved reaction of K2 with various aromatic aldehydes, yielding the Schiff bases derivatives Q1-Q5. The chemical structures of these compounds were identified by FT-IR,1H NMR and 13C NMR spectroscopy. The newly synthesized derivatives (Q1-Q5) were subjected to rigorous evaluation to assess their efficacy as corrosion inhibitors for ca

... Show More (3)

(3)

(4)

(4)

(8)

(8)

(7)

(7)

The electrochemical behavior of Al-17%Si alloy is investigated in 3.5wt% NaCl solution. Many alloys with addition of the different wt% magnesium metal of 1wt%, 2%, 3wt% ,4.5wt% ,and 9wt% were prepared by gravity die casting . The microstructures of prepared alloys were examined by optical and SEM microscopes. Corrosion behavior was investigated by using potentiostat instrument under static potentials test and corrosion current was recorded to determine corrosion resistance of all prepared samples. It was found that the addition of Mg metal improves the corrosion resistance of Al-17%Si alloy in 3.5%NaCl solution. The alloy containing 1%Mg shows less corrosion rate than the others while the alloys containing 4.5%Mg, 9%Mg content have

... Show More (2)

(2)

This study deals with the corrosion inhibition of metal corrosion process of medium carbon steel using 1M HCl for kinetic studies and rate reaction determination. The weight loss method is applied to pieces of Medium carbon steel divided to Cubans with dimensions (0.4*2*2.4) cm , and use Tafel Extrapolation Method, the samples were polished using carbide silicon paper with dimensions of (180,200,400,600,800,1000). The samples were immersed in the alcoholic medium ethanol at a temperature 293K for 3hr. Natural inhibitor Kujarat Tea (Hibiscus sabdarriffa L.) is used which is extracted in aqueous and alcoholic medium, different concentrations (1000،2000, 3000) ppm have been used ; The best concentration found through the results is a

... Show MoreThis study deals with the corrosion inhibition of metal corrosion process of medium carbon steel using 1M HCl for kinetic studies and rate reaction determination. The weight loss method is applied to pieces of Medium carbon steel divided to Cubans with dimensions (0.4*2*2.4) cm , and use Tafel Extrapolation Method, the samples were polished using carbide silicon paper with dimensions of (180,200,400,600,800,1000). The samples were immersed in the alcoholic medium ethanol at a temperature 293K for 3hr. Natural inhibitor Kujarat Tea (Hibiscus sabdarriffa L.) is used which is extracted in aqueous and alcoholic medium, different concentrations (1000،2000, 3000) ppm have been used ; The best concentration found through the results is a conce

... Show More (2)

(2)

The compressive residual stresses generated by shot peening, is increased in a direct proportional way with shot peening time (SPT). For each metal, there is an optimum shot peening time (O.S.T) which gives the optimum fatigue life. This paper experimentally studied to optimize shot peening time of aluminium alloy 6061-T651 as well as using of and analysis of variance (ANOVA).

Two types of fatigue test specimens’ configuration were used, one without notch (smooth) and the other with a notch radius (1,25mm), each type was shot peened at different time. The (O.S.T) was experimentally estimated to be 8 minutes reaching the surface stresses at maximum peak of -184.94 MPa.

A response surface methodology (RSM) is presen

... Show More (1)

(1)

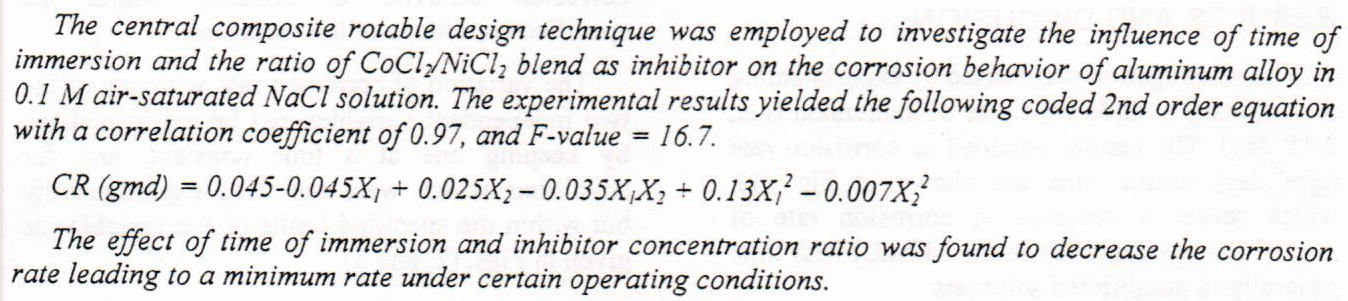

Cooling towers is one of the most important unit in industry, they are used to dispose heat from cooling media used in the integrated units. The choice of the cooling media plays recently an important rule due to fresh-water scarcity. The use of saline as a cooling media become of growing interest, but the corrosion problem has to be taken in consideration. In this study the simultaneous effect of cooling tower operation parameters on the corrosion rate of mild-steel is considered. The role of NaCl content is found to be pronounced more than the working solution temperature and flowrate. The corrosion of mild-steel in these studied factors had shown an interesting result especially with the NaCl% content. Firstly, there was an increase in t

... Show More (6)

(6)

(2)

(2)

a porentioncsisteve has been carried out of the corrosion behavior of inconel(600) in chloride ions (Cl) over the tempreatures 293 over the temperatures 308K in both the dcacrated and the alloy